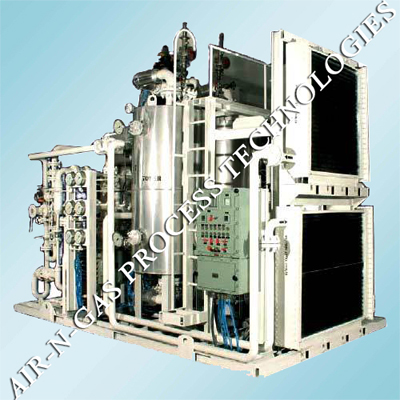

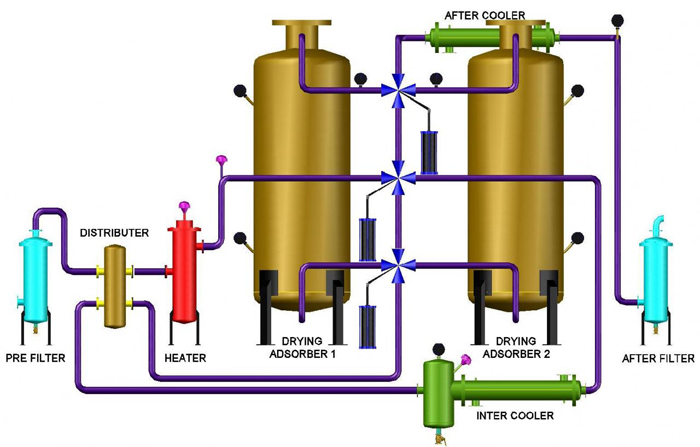

Split Flow No Purge Loss Dryer

To save on purge loss, here part of wet air is circulated through a heater thereby increasing its moisture carrying capacity, which is used for regeneration. In this type of dryer incoming wet air is divided in a distributor. 60-70% of wet air goes for drying while 30-40% of wet air is circulated through a heater thereby increasing its temperature which then takes out the moisture from desiccant bed and then it is cooled in an after cooler where moisture is condensed and drained out in moisture separator. This air is sent back to the distributor where it mixed with incoming air and distributed again.

Salient Feature:-