Medical Oxygen Generator

EQUIPMENTS ARE FABRICATED IN ACCORDANCE WITH ALL RELEVANT CODES LIKE…

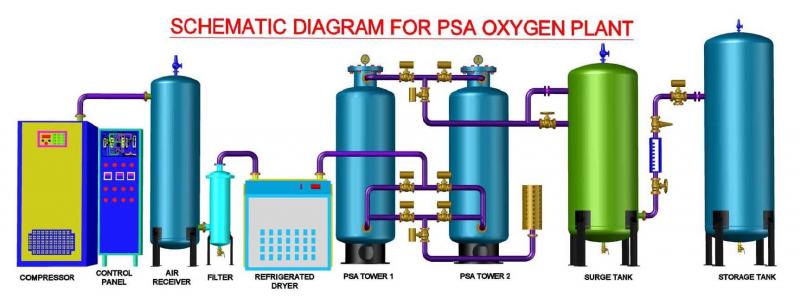

Process Description

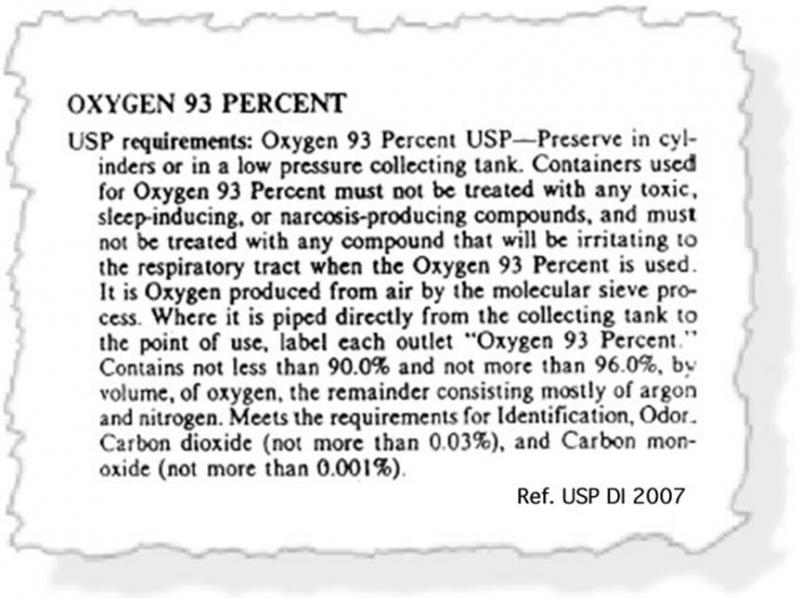

In this system, when compressed air is passed through adsorption tower field with Z.M.S, the molecules of nitrogen, moisture & other unwanted gases are adsorbed on a surface of Z.M.S and oxygen which is not adsorbed by Z.M.S comes out of adsorption tower. This oxygen is collected in a surge vessel. Two adsorption towers are used for continuous generation of oxygen gas, which are interconnected with auto-changeover valves controlled by Programmable Control Panel (PLC) in the control panel. After saturation of one tower with oxygen, the process automatically changes over to another tower resulting in the continuous production of oxygen gas for long.

MAJOR COMPONENTS OF PSA SYSTEM

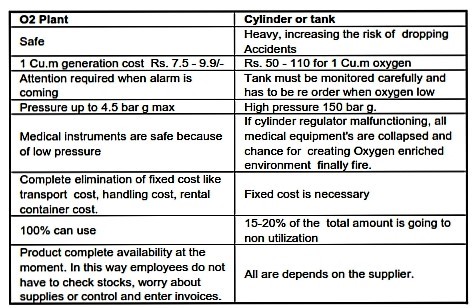

BENEFITS OF ON-SITE OXYGEN GAS GENERATION PLANT